Capabilities

Your Vision, Our Capacity

24+ years of mastery in injection moulding, tooling, and bespoke plastic solutions for global OEMs. From concept to mass production, we turn complexity into reliability.

Custom Manufacturing

Your Vision, Our Precision

Tailored solutions for industries demanding exacting standards:

✅ Micro-Moulding : Parts as light as 0.03g with 50-micron tolerances

✅ Material Versatility : 20+ polymers, including glass-filled nylons, Mineral Filled, and biodegradable resins

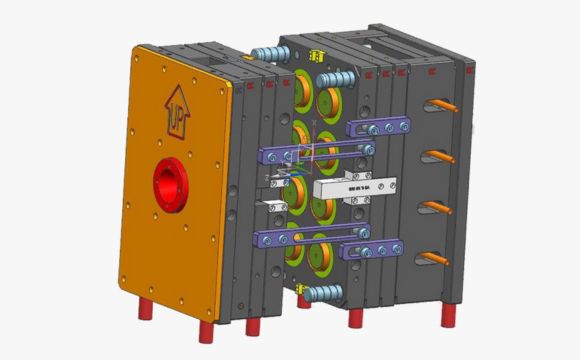

✅ Custom Tooling : 500+ active moulds in production

Design & Development

From Concept to Perfection

Our team will partner with you to refine designs for manufacturability, material efficiency, and performance. Leverage our expertise in:

✅ 3D CAD modeling & prototyping

✅ Tolerance optimization (±0.05mm)

✅ Optimal Material Selection to ensure best stability & repeatibility of part

✅ Mould Flow Analysis

✅ DFM (Design for Manufacturability) analysis

✅ Tool Development & Manufacturing

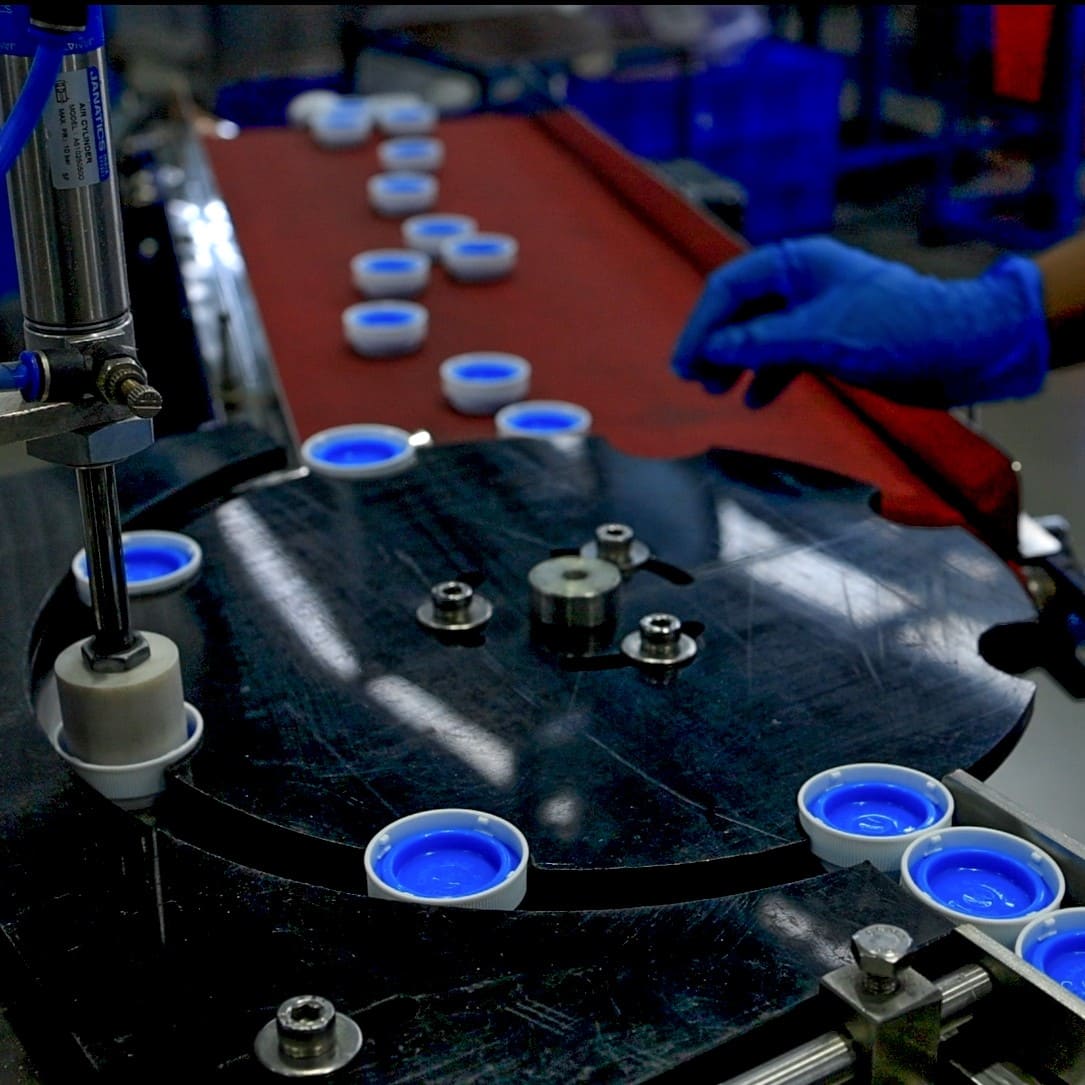

High Volume Production

Scalability Without Compromise

Trusted by Fortune 500 OEMs for high-volume production.

✅ Speed : Cycle times as low as 7 seconds

✅ Capacity : 160 metric tons/month across 39 machines (50T–250T)

✅ Consistency : Automated vision inspection for 99.9% defect-free output

Clean Room →

Ultra-Clean Manufacturing

Class 10,000 environment for medical, pharmaceutical, and biotechnology products

✅ Cleanliness : ISO Class 10,000 (ISO 6) Environment

✅ Filtration : HEPA filters removing 99.97% of particles

✅ Compliance : Dedicated for Medical & High-Purity Products

Beyond Moulding with Complete Finishing and Assembly Under One Roof

Secondary Operations

At Mascot Plastic Industries, we extend our expertise beyond injection moulding to offer a full suite of secondary operations that elevate your product’s functionality and visual appeal. Our integrated post-moulding services ensure precision, efficiency, and scalability, making us your one-stop manufacturing partner.

Pad Printing →

Multi-color surface branding on complex shapes

Labeling →

High-adhesion labels for industrial and retail applications

Assembly →

Manual and semi-automated component integration

20+ Polymers | Global Standards | Tailored Solutions

Polymer Portfolio

At Mascot Plastic Industries, material science isn’t just a process—it’s our passion. With 15+ advanced polymers in our arsenal, we transform raw granules into high-performance components for industries demanding precision, durability, and compliance.

1. Engineering Plastics for Extreme Conditions

Polyamides (Nylon) :

🔴 PA6 (Unfilled | Glass-Filled 15-40% | Mineral-Filled)

🔴 PA66 (Unfilled | Glass-Filled 15-50 % )

🔴 PA46 (Unfilled | Glass Filled 15-50% | Carbon Filled 15% | FR (V2-V0) )

Polyacetals (POM) :

🔴 Homopolymer & Copolymer grades for low-friction, high-stress applications.

High-Performance Polymers:

🔴 PPS (Polyphenylene Sulfide): Chemical/heat resistance for automotive & electronics.

🔴 PES (Polyethersulfone): Sterilizable medical components.

2. Clarity & Impact Resistance

🔴 Polycarbonate (PC): Clear & colored variants for lenses, medical devices, and consumer goods.

🔴 ABS: Tough, aesthetic parts for automotive interiors and electronics.

3. Sustainable & Specialty Solutions

🔴Biodegradable Resins: Compostable packaging and eco-friendly products.

🔴 TPE (Thermoplastic Elastomers): Flexible seals, grips, and soft-touch components.

🔴 PPO (Noryl®): Flame-retardant housings for electrical systems.

4. Commodity Polymers with Precision

🔴 Polypropylene (PP): FDA-compliant for pharma packaging.

🔴 HIPS, HDPE, LDPE: Cost-effective solutions for consumer goods and industrial parts.

🔴 Polystyrene (PS): Rigid, lightweight packaging and disposable products.

Store Area

Store CSS Line Area

Lab Facility

Training & Conference Room

Class 10,000 Clean Room

Inspection Department

Workshop Area

Maintenance Department

Printing & Assembly Department

Labeling Department

2

Manufacturing Units

60,000

Spread Sq. Ft. Area

39

Injection Moulding Machines

160

Metric Tons / Month Capacity

Industry Solutions Showcase

Precision Crafted for Your Industry

Trusted by Leaders

Proven by Performance

Our Company

About Us

Manufacturing Facility

Capabilities

Quality Assurance

Sustainability

Clientele

Portfolio

© 2026 Mascot Plastic Industries. All Rights Reserved.

Language

English